The majority of fuel additives are a blend of 1-3 ingredients/chemicals. However, the more effective premium additives typically have 4-6 ingredients. The first ingredient in the low cost additives is usually a carrier or base used to give the product more volume and a means for diluting the more active ingredients.

It is very similar to the way they package bleach/chlorine. You can buy it in retail stores at different strengths, typically 3.5% for lowest cost, regular household strength at 5% is mid-price and pool chlorine at 10% is more expensive. It is all chlorine just diluted with more water to get the different concentrations for efficiency and price levels. The point is water is the carrier used to blend with the chlorine. You are buying mostly water which is an inactive ingredient.

This also typically holds true for fuel additives, the base is usually naphtha/Stoddard solvent which is essentially the same as kerosene or lamp oil. Then the producers add their package of chemical ingredients that modify the characteristics of fuels and make the additive unique to them. The combination of chemicals in the added package is far more expensive and usually each one has single use characteristics. Meaning they may be a good stabilizer or lubricant or booster or water dispersant, etcetera. There is no single chemical that is effective in all of those areas so several chemicals must be blended together to produce an effective multipurpose product.

For the producer this presents a dilemma, how do I blend a product that is low cost, low dosage, easy to package and still effective? In addition the most effective chemicals in each of those categories are more expensive and not necessarily compatible when blended together. They may not blend together well similar to oil and water, or stayed blended while sitting on the shelf for extended periods. Certain blends may attack their plastic container so special coatings are required plus there are many more considerations; the complexities of developing, blending and packaging a truly effective fuel additive is staggering.

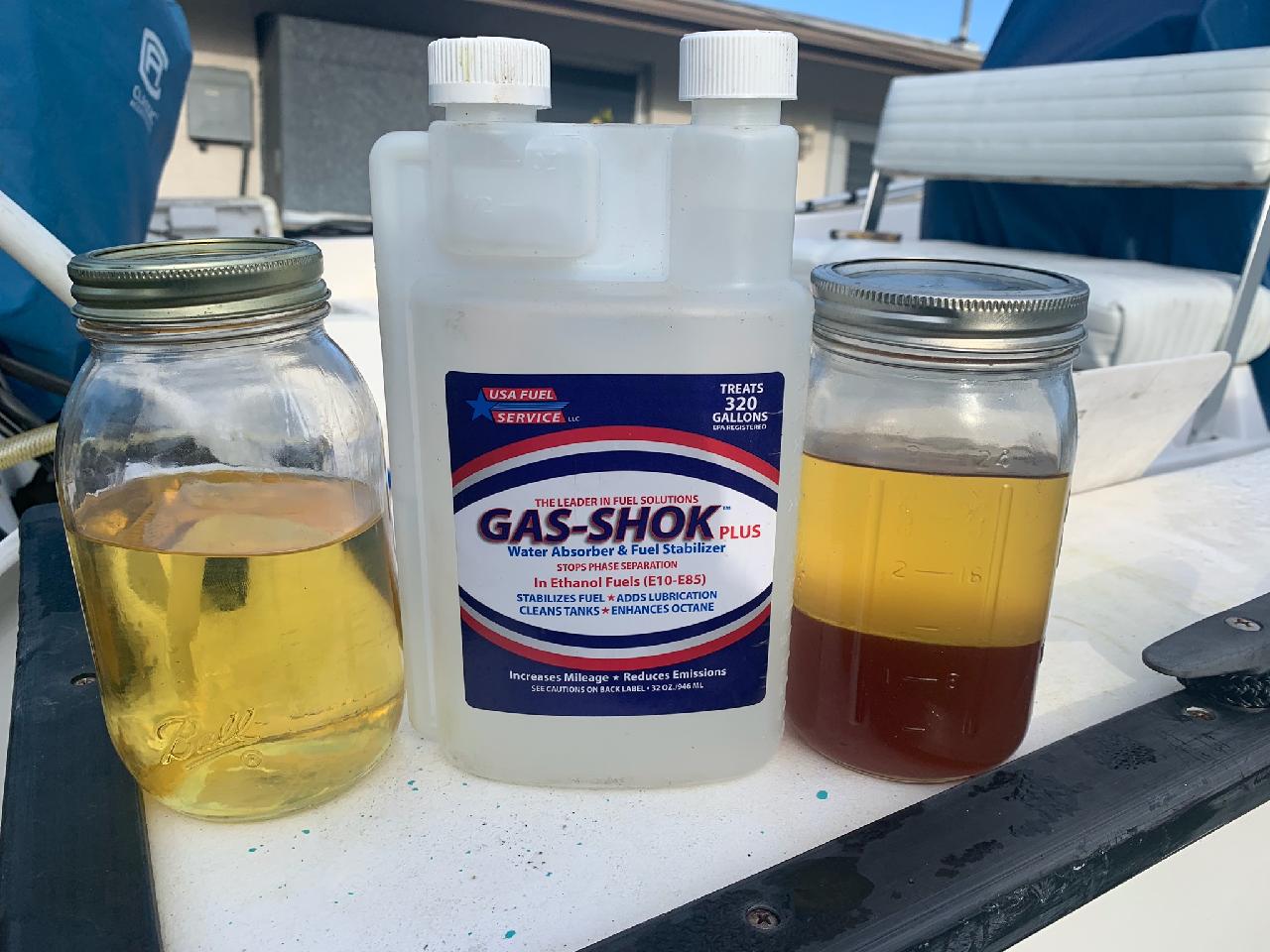

Many producers solve the problems with compromises that can be confusing, misleading and can be more costly to consumers. The two most popular methods of solving the packaging and cost issues simultaneously is to dilute the product to where it does not attack the plastic container and/or separating the ingredients that makeup a full range fuel additive into two or three individual products. The consumer then has to buy two or three different products/bottles to get the same protection provided by a broad spectrum premium additive. They end up actually paying more with a low cost narrow spectrum product, especially if they have fuel issues and/or engine damage.

The bottom line is to realize as with any consumer item, the less expensive products will usually never be the best in category, quality will always cost more. Many of today’s products have very cleverly written labels to entice and sometimes mislead consumers into purchasing a marginal or less effective product.

When selecting a fuel additive always start with skepticism and use common sense, read the label carefully, consider the price within the category, make sure it does not affect warranties or harm gaskets, seals or engine components, read about the company on its website, , and look for testimonials with names disclosed.

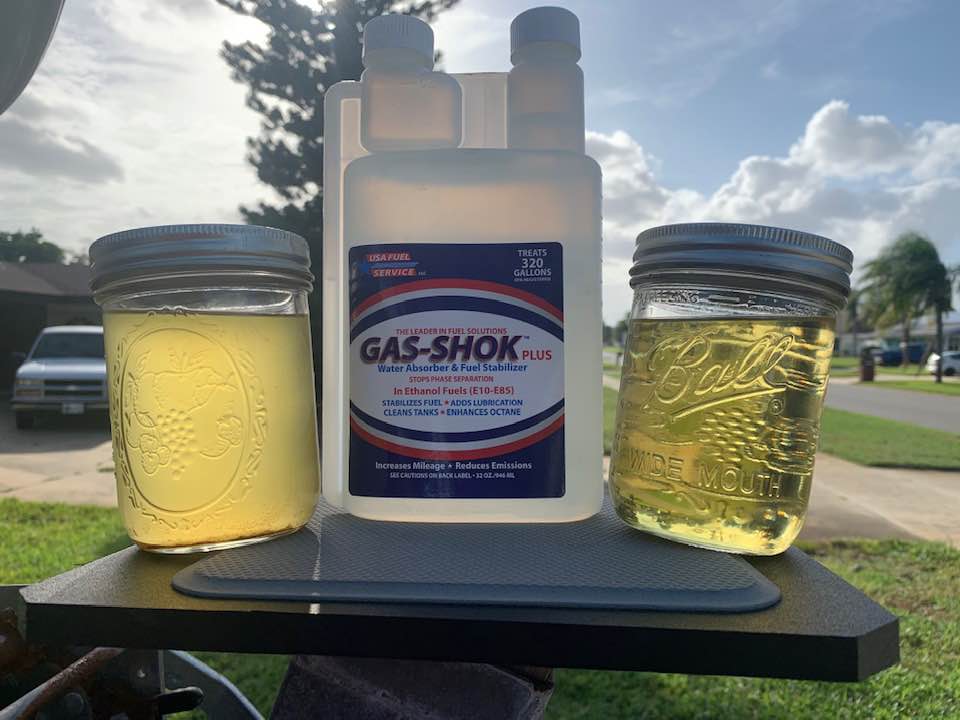

Most premium fuel additives will be in the upper price range but they can provide a full range of benefits in one bottle instead of two or three. If you use a fuel additive that is a stabilizer, lubricant, combustion modifier and controls water you will eliminate the problems that cause over 70% of engine failures. For more information about our premium fuel additives see our products page.

© All rights reserved, www.usafuelservice.com